聯絡資訊

謝謝您訪謄騏國際股份有限公司的網站,如果您對我們的產品有任何問題請留下您的訊息,我們將盡快的回覆您。

MORE>

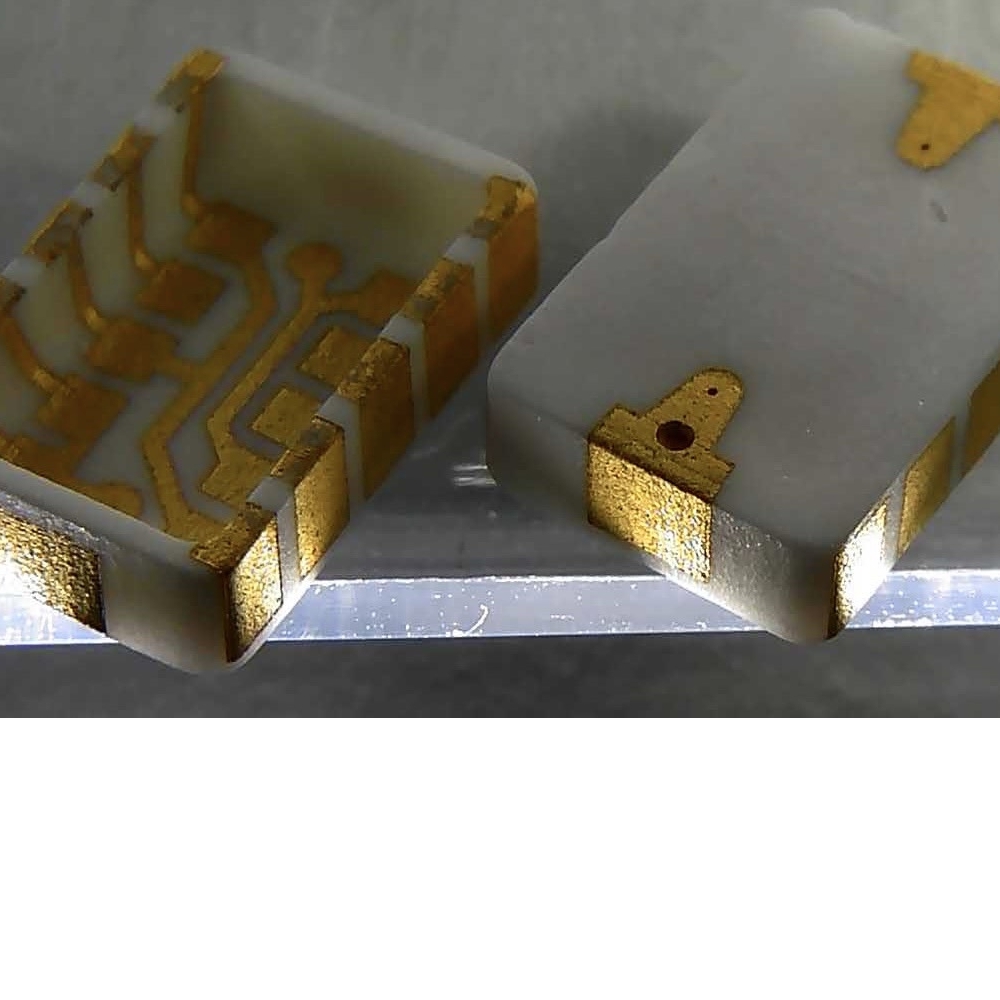

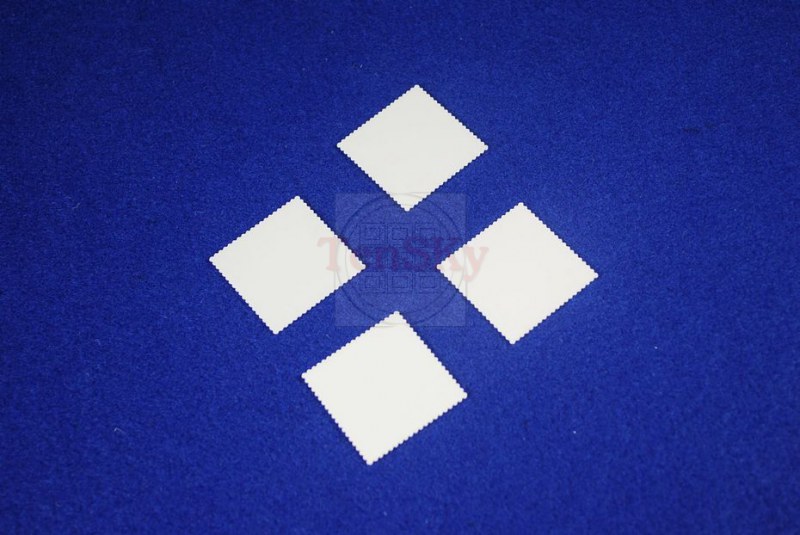

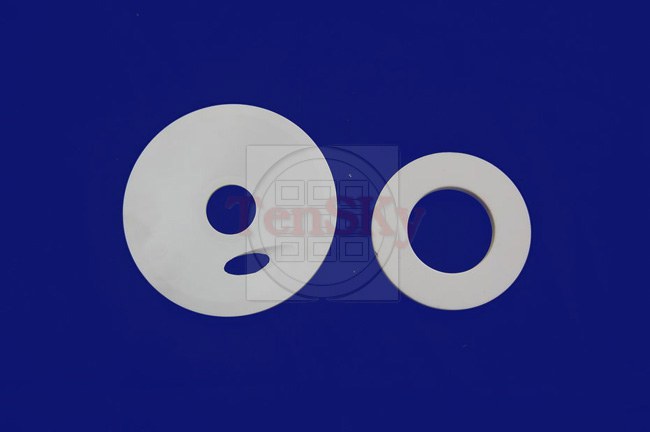

本公司成立於2007年,本著專業、品質、效率的信念,不斷針對陶瓷相關產品的應用創新、研發相關產品,解決業界各種需求。

目前著重於,電子陶瓷/陶瓷電路板事業、結構/精密陶瓷陶瓷事業、塗料及表面處理事業等三大事業體創新與研發。

TSK 在中國大陸、日本、韓國、俄羅斯、美國、德國、新加坡、法國等地皆有合作的客戶,十年以上陶瓷加工經驗生產專業、海內外陶瓷專業及PCB、半導體產業專業技術,效率追求第一,並力爭超越顧客期望。

謝謝您訪謄騏國際股份有限公司的網站,如果您對我們的產品有任何問題請留下您的訊息,我們將盡快的回覆您。

MORE>